With the proposal of the national "dual carbon" goals, for newlybuilt or renovated water treatment projects, when purchasing pumps, the energy efficiency of both the water pump and the motor should be specified simultaneously to maximize energy conservation and emission reduction. Among them, the efficiency of the water pump and the energy efficiency of the motor indicate the efficiency of converting electrical energy into mechanical energy. The higher the energy efficiency, the larger the proportion of electrical energy converted into useful work, and the lower the energy consumption during the motor's operation.

By connecting to the controller PLC, the Wutongbolian industrial intelligent gateway can collect realtime data such as motor operating temperature, voltage, current, power, as well as water pump startstop status, flow rate, and water pressure. These data are transmitted to the cloud platform or local upper computer via 5G/4G/WIFI/Ethernet, thereby realizing energy efficiency monitoring and online management of the water pump and motor. This enables flexible setting of operating strategies such as motor frequency and water pump startstop, ensuring the safety of water supply and drainage while achieving energyefficient operation of the water pump.

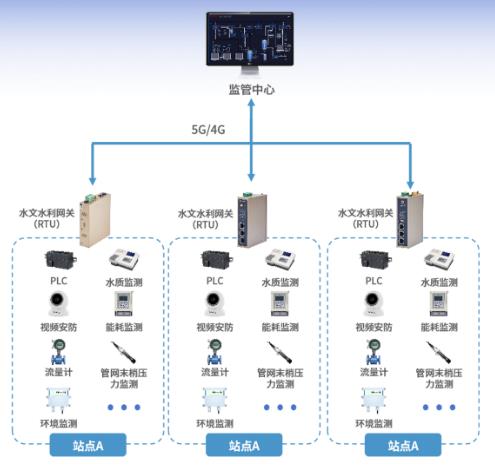

System Architecture

1. Equipment Layer: PLC connects to equipment such as water pumps, motors, temperature sensors, pressure gauges, and flow meters to achieve automatic control.

2. Gateway Layer: The gateway connects to the PLC for data collection and edge computing, and transmits the collected data to the monitoring platform.

3. Platform Layer: The monitoring platform realizes visual monitoring, alarm, management, control, and data analysis of the water pump and motor.

Realized Functions

1. Realtime monitoring of parameters in the pump station, such as water level, pressure, flow rate, temperature, voltage, current, and the operating status of the water pump. It enables remote access via phones and computers.

2. Automatic alarm via WeChat, SMS, email, etc., to notify relevant personnel for handling, allowing them to quickly understand the alarm information and minimize downtime and losses as much as possible.

3. Network cameras can be connected to achieve remote management of the pump station via phones and computers, improving management efficiency while reducing management costs.

4. Realize data analysis of the operating conditions of the water pump and motor, understand parameter changes under different conditions, so as to formulate scientific and reasonable decisions and achieve efficient and energysaving operation.

5. In case of emergencies, managers can remotely control the water pump switch and motor startstop, improving the fault response capability and ensuring the safe and reliable operation of onsite equipment.

With the proposal of the national "dual carbon" goals, for newlybuilt or renovated water treatment projects, when purchasing pumps, the energy efficiency of both the water pump and the motor should be specified simultaneously to maximize energy conservation and emission reduction. Among them, the efficiency of the water pump and the energy efficiency of the motor indicate the efficiency of converting electrical energy into mechanical energy. The higher the energy efficiency, the larger the proportion of electrical energy converted into useful work, and the lower the energy consumption during the motor's operation.

With the proposal of the national "dual carbon" goals, for newlybuilt or renovated water treatment projects, when purchasing pumps, the energy efficiency of both the water pump and the motor should be specified simultaneously to maximize energy conservation and emission reduction. Among them, the efficiency of the water pump and the energy efficiency of the motor indicate the efficiency of converting electrical energy into mechanical energy. The higher the energy efficiency, the larger the proportion of electrical energy converted into useful work, and the lower the energy consumption during the motor's operation.

Go Top

Go Top